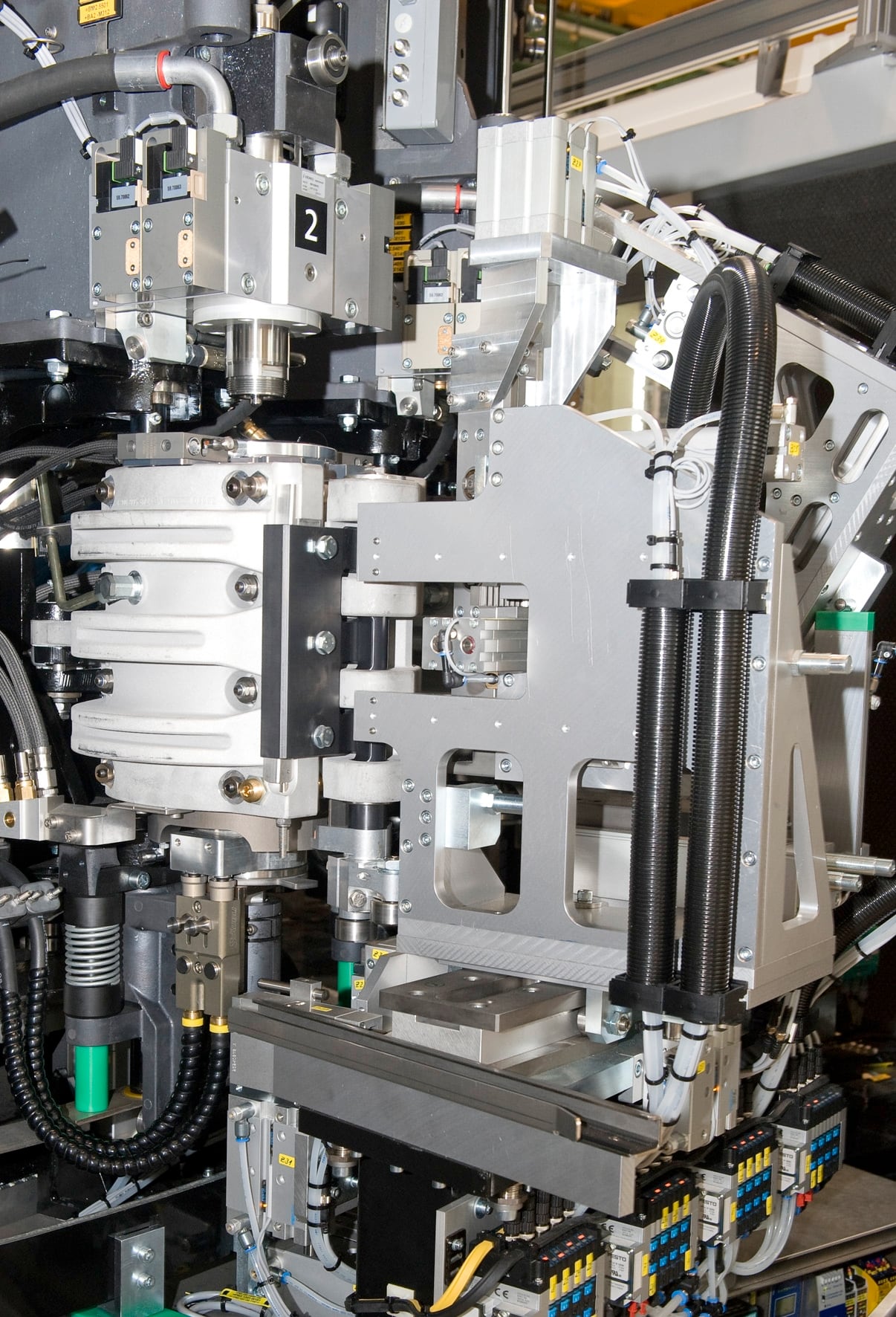

The Germany-based equipment maker said the semi-automatic system is integrated into the blowing wheel to shorten the change-over time from about 3.5 minutes to less than one minute per blow-molding station.

Target market

This improvement will be of particular interest to consumers who have to change their moulds very often because they produce small charges and/or have many different kinds of bottle forms.

Krones said the MouldXpress Advanced reduces the change-over time through the dual work of the machines and the operator.

Explaining how this works, Krones said that as the first station is prepared for change by the MouldXpress Advanced (unlocks mould hanger, opens, and unlocks the mould), the operator can simultaneously change the moulds and the second station of the MouldXpress Advanced connects the changed mould (locks the mould, closes, and locks the mould hanger).

The different moulds are kept securely in a changing trolley with designated compartments to allow easy identification, and reduce the risk of installation error. A rotating function keeps the removal position in the same place for the operator.

Simplification

Running through the benefits of the MouldXpress Advanced, Krones said that apart from the savings on the change-over time, the new system simplifies the work of the operator. The change-over is less onerous for the operator because no tools are needed, and consistent quality is more easily maintained.

The MouldXpress Advanced may be used in Contiform blow-moulding machines of the S16 to S28 series for the standard process, and for relax-type moulds with neck-cooling.

Krones said the cost of the MouldXpress Advanced depends on the size and configuration of the machine. And the return on investment varies according to how often the consumers change their moulds.