Fermentation involves the conversion of glucose in the wort by yeast into alcohol and CO2. When the process is complete after 4-6 days most of the yeast settles to the bottom of fermentation tanks.

This yeast is then removed and reused several times before storage in an excess yeast tank – it is then sold off as animal feed.

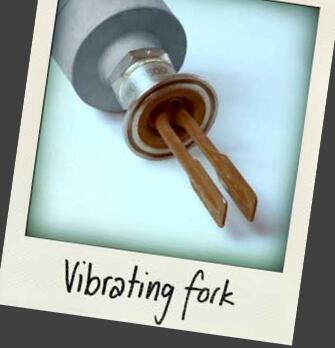

“In this final stage of filling the excess yeast tanks, Carlsberg experienced overflow problems due to the heavy build-up of foam which was preventing triggering of the traditional level vibrating forks [pictured bottom].”

‘Frequency sweep’ technology

Carlsberg solved the problem by using a Baumer CleverLevel LBFS/LFFS switch (photo left) to detect filling levels in yeast tanks. This uses ‘frequency sweep’ technology and suits wet, dry and sticky media or foam.

Baumer said the switch is more effective than traditional forks since only one version is needed for sticky media, dry media and wet media – CleverLevel can be used throughout the beer production process from the arrival of barley in storage tanks to the finished beer.

The switch is maintenance free, has a shallow mounting depth of 15mm and can be configured visually using accompanying software and a ‘FlexProgrammer’ to suppress or not suppress foam.

Could solve Carlsberg’s CIP problems

The CleverLevel switch can also be used to detect contaminants in media (for instance, residual cleaning agents) and protect pumps from running dry.

Lone Højbjerg Peterson, maintenance co-ordinator at Carlsberg Denmark, said: “The CleverLevel switch has solved our problems with overflow in the excess yeast tanks due to its unique and easy configuration options.”

Benefits to Carlsberg include less yeast entering the sewage system – an environmental advantage – and cost savings due to process optimization and a reduction in maintenance.

“We are now considering using it in our CIP caustic tanks, where we experience similar issues with foam and overflow,” Peterson added.