For more than two decades, the standard Champagne bottle has remained unchanged at 835g. While leaps and strides have been made in lightweighting glass bottles to create more eco-friendly options, Champagne has been a difficult nut to crack because of the pressure requirements of the sparking wine.

This month, however, Champagne Telmont debuts its 800g bottle in the US market after several years of R&D and testing.

Small changes make big impact

A reduction of 35g might not sound much: but glass is a big source of carbon emissions in the Champagne industry (bottle manufacturing accounts for nearly 30% of Champagne’s carbon foodprint).

Lighter bottles contain less glass: which means less carbon emissions from glass melting and production.

Furthermore, the reduction means less fuel for transport (both upstream and downstream): important for a product that is shipped around the world. With the quantities of Champagne produced and transported, small reductions in each bottle can make a big difference.

Reducing the impact of transportation

Champagne Telmont's bottle cuts carbon emissions by 4% per unit compared to the previous industry standard.

That reduction becomes exponentially impactful at scale and helps lower the carbon footprint associated with transport, one of Champagne’s largest emission sources.

And the 35g is just the latest reduction made over several years (Champagne bottles previously came in at around 900g). And technical challenges become greater the more the weight is reduced.

In fact, the gas from Champagne inside the bottle is around twice that of the pressure inside a car tire.

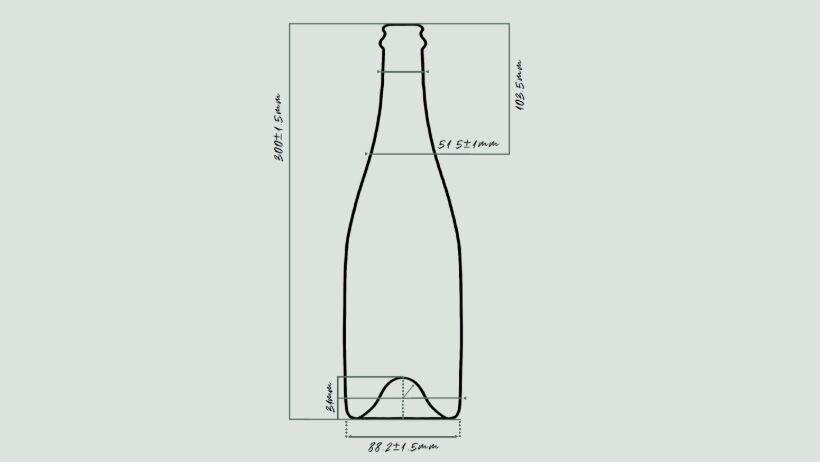

In conjunction with French glassmaker Verallia, Telmont developed a lighter bottle that still maintains the essential pressure resistance and refined aesthetic expected from a premium product.

It began producing the 800g bottles in 2022 with an initial run of 3,000 bottles. Following the three year aging process, the bottles are now hitting shelves in the US.

Production has already been scaled up: 220,000 bottles were produced in 2024 and from 2025 onwards, all bottles will be produced at this new, lighter weight.

“Since initially creating the bottle in 2022, we learned that a sustainably driven design can meet and even surpass traditional standards for performance and quality,” Ludovic du Plessis, president of Champagne Telmont, told us.

“Our 800g eco-designed bottle, crafted from 87% recycled glass in partnership with French glassmaker Verallia, has been a major milestone in our sustainability journey.

“Since the initial production run, we’ve rigorously tested and monitored the bottle’s durability in transit, pressure resistance and handling in real-world environments. With over 250,000 bottles produced to date, it has exceeded expectations, not only in performance but also in aesthetics showing that sustainability does not require compromise.”

Fit for a sommelier

Will the consumer notice any difference with the lightweight bottle?

Yes, says du Plessis – in a good way.

“The 800g bottle is lighter, an element that has garnered positive response from consumers and sommeliers alike,” he said.

“It offers an ease when handling and pouring, especially in service settings, while still maintaining the traditional look and feel expected from Champagne.

“But most importantly, it represents something bigger: a tangible step toward reducing Champagne’s environmental impact.”

In the Name of Mother Nature

The lightweight bottle is just one measure from the Champagne house, which is backed by Leonardo DiCaprio and is targeting net zero carbon emissions by 2050. It is also on a quest to convert all of its vineyards to organic and regenerative agriculture (around 70% of vineyards are already certified organic) via its program, In the Name of Mother Nature.

Furthermore, the house no longer uses transparent glass (which does not contain recycled content) and bespoke bottles (which typically weigh more than standard Champagne bottles at 900+ grams).

Driving a widespread shift in Champagne packaging standards

Champagne Telmont is making the tech behind the bottle available to other Champagne producers.

If the bottle was adopted across the Champagne industry, it could eliminate 8,000 tons of CO2 emissions per year, according to its estimations.

The innovation does not require any modifications to the production process or manufacturing equipment, which should help encourage uptake.

That, says du Plessis, means there are ‘no barriers whatsoever to its immediate and widespread adoption as a new standard for the appellation’.

“We strongly believe that sustainability should not be a competitive advantage, rather a collective responsibility,” he said.

“There is no exclusivity on this 800g bottle, it is indeed available to the entire Champagne industry, and it could soon become the new, lighter standard for the appellation.

“The benefits are clear: reduced emissions, alignment with consumer expectations, and a stronger collective voice for sustainability: a transformational shift for the Champagne industry.”