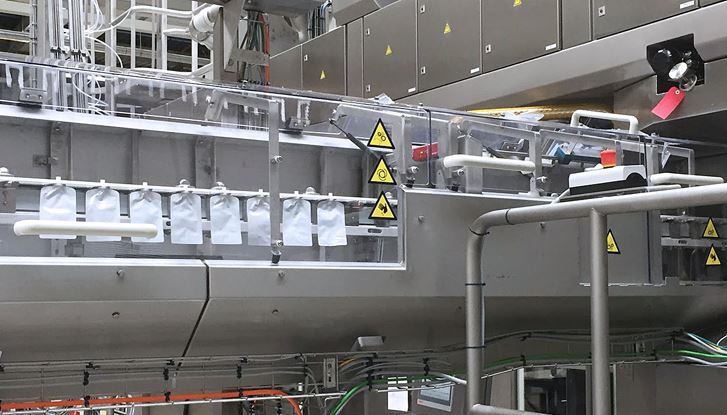

The filling system can fill a range of products from water-like liquids to high viscous products, such as smoothies with particulates.

Shelf life

It can also be equipped with a nitrogen dosing system to reduce the oxygen in the headspace of the pouch, which limits the chemical deterioration (oxidation) of the product, helping maximize product shelf life in the process.

The company says it has already received its first order from a company in Europe for infant nutrition.

“Apart from capacity and aseptic integrity, the AsepFlex Filler offers flexibility,” said Bert Krakers, product manager, JBT.

“Pouch formats and sizes can be changed on the fly without the necessity to change parts.”

According to JBT, the flexible packaging market is growing, with pouches becoming the preferred option for processors and consumers because they are non-breakable, lightweight, easy to open, and easy to empty (squeezable) characteristics.

For example, flexible pouches in the infant nutrition category are expected to grow their market share by 10% each year.

But Krakers claims growth is restricted by limits to current pouch filling technology.

Plastic bottles

He added, technology using an aseptic form fill seal typically have a low capacity and a high Total Cost of Ownership (TCO) due to a high rejection rate. And, hot fill with retort sterilization has low (120ppm) capacity and low product quality.

Krakers said the JBT AsepFlex Linear Pouch Filler has been developed to solve these problems by improving capacity and operational performance.

Its technology has a capacity as high as 500 ppm (30,000 pouches per hour) and is designed in accordance with FDA guidelines for low acid aseptically filled food products with an operational 95% efficiency rate and reject rate of 0.5%.

The AsepFlex filler can also be technically configured for multi-flavor filling or filling plastic bottles and pouches on the same machine.