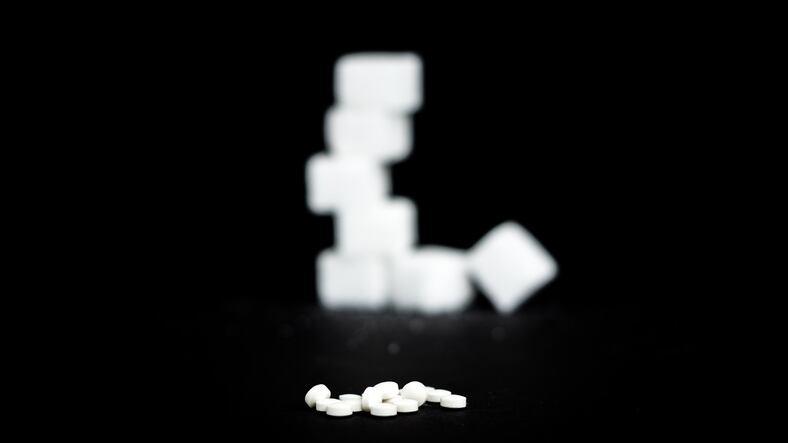

Rare sugars hold great potential for practical applications – as sweeteners, for instance – in the food industry. But few have been exploited commercially due to their scarcity in nature, which prevents them from being isolated in large quantities.

Nigerose is a rare sugar with potential immune-boosting and probiotic effects. It occurs in nature as a constituent of polysaccharides such as nigeran. It is also found in Japanese rice wine or sake, hence its alternative name, sakebiose.

“Nigerose has been shown to exert immunopotentiating activity in mice; it has potential as a prebiotic; it has been evaluated as an additive in cryopreservation media for human cell lines and it has been applied as a building block for promising biocompatible nanocarriers for sustained drug delivery.”

Previous methods of producing nigerose were too expensive

Previous research discovered that nigerose could be synthesized by adding the powerful solvent DMSO. But this process was found to increase overall production costs. Researchers at Ghent University, in a study published in the Royal Society of Chemistry journal, looked at the alternatives for the “efficient synthesis of nigerose from sucrose and glucose” without using DMSO, “thereby adding to the inventory of rare sugars that can conveniently be produced from bulk sugars.”

They discovered a cheap and convenient way of making enough nigerose from table sugar so that its potential use in the food industry can be explored.

The researchers designed a mutant transglycosylase “that allows the rare disaccharide nigerose to be produced efficiently and conveniently, starting from cheap, renewable and abundant bulk sugars in aqueous solution,” they wrote.

"Because nigerose can now easily be produced on multi-gram scale as was demonstrated in this work, its properties can be thoroughly evaluated moving forward. Furthermore, the process can readily be scaled up for potential industrial purposes.”