Developed in partnership with 3DomFilaments, the material was unveiled at the TCT Show 2014, for 3D printing, additive manufacturing and product development, at the NEC in Birmingham, UK, (September 30-October 2).

Higher print speeds

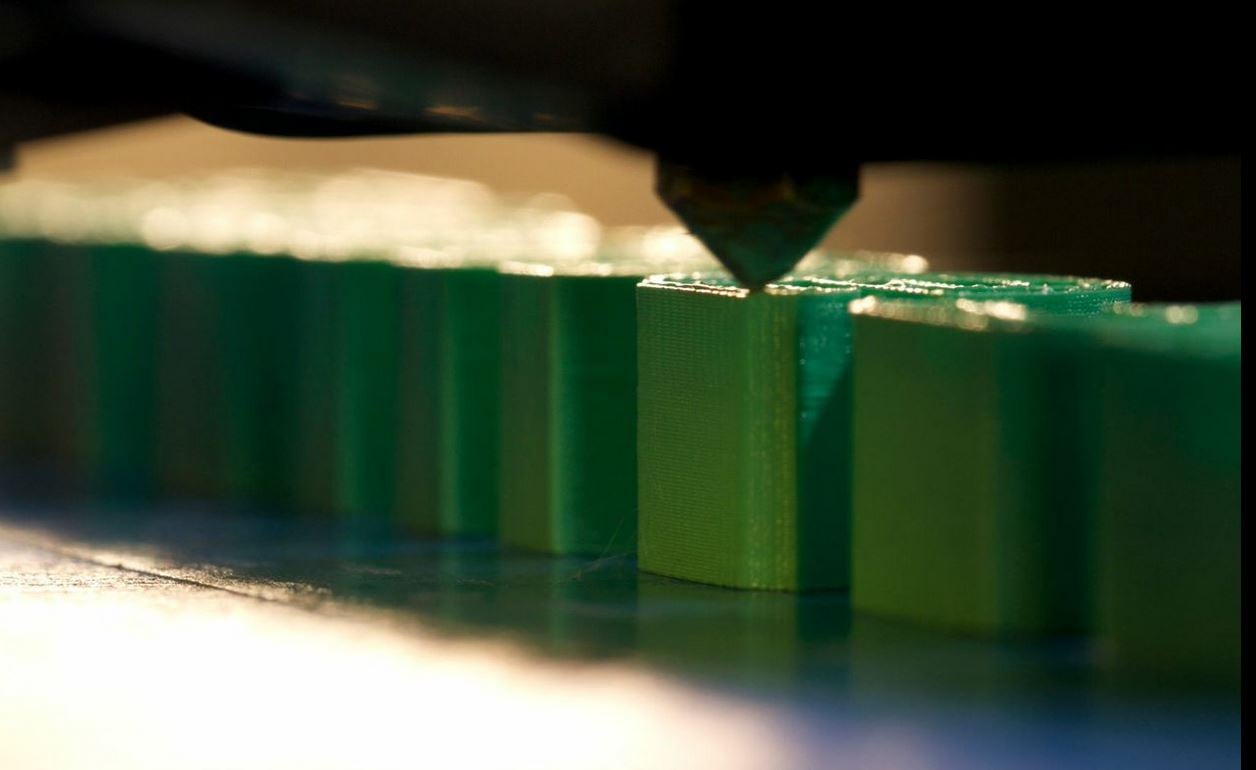

Sally Morley, sales director, Biome Bioplastics, told FoodProductionDaily, like other plant-based plastics on the market, Biome3D processes more easily than oil-based plastics. However, unlike other plant-based printing filaments it has a surface finish and flexibility closer to that normally found with oil-based plastics. It also runs at higher print speeds of 80–100 mm/s.

“The future of bioplastics lies in demonstrating plant-based materials can outperform their traditional, oil-based counterparts,” she said.

“Biome3D’s thermal and flow characteristics achieve excellent printed detail, with minimal shrinkage, cracking or warping. It can run at higher print speeds, giving customers great results, faster.”

Plant-based plastics

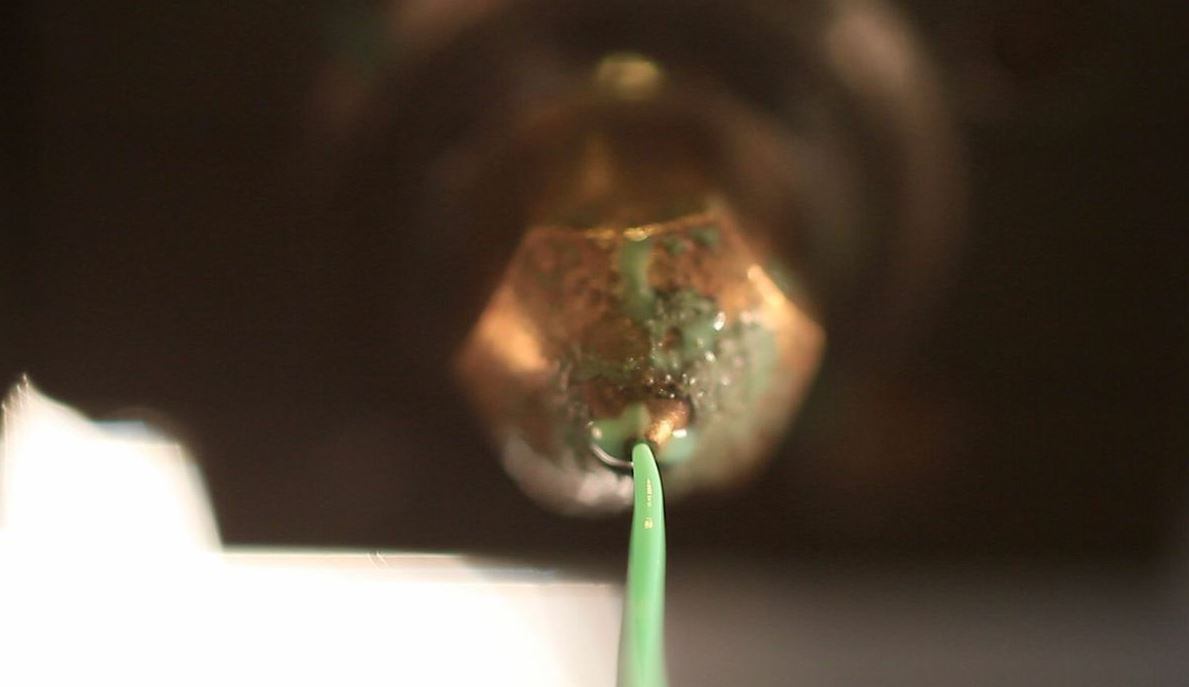

Biome3D can extrude at nozzle temperatures from 180–225°C depending on the printer design. A nozzle diameter of 0.4 mm is recommended.

According to Morley, plant-based plastics are already a popular choice for 3D printing because they are easier to work with during processing, and are food safe and odour free.

She said they are a great example of how sustainable alternatives can gain market share based on their performance, rather than just their ‘green credentials’. However, oil-based printing filaments are still used because they have a higher softening point and make more flexible models that will bend before they break.

Biome Bioplastics develops plant-based plastics for a range of applications, from food, and catering to electronics and its partnership with 3Dom Filaments is its first move into the 3D printing industry.

Compostable coffee pod

It claims it wants to challenge the dominance of oil-based plastics and changing perceptions of biopolymers. Last year,it launched the first compostable coffee pod.

Based on the success of the biodegradable pods, the firm is now working with manufacturing and brand partners to develop a number of natural polymer-based products for the hot drinks industry, with further announcements expected this year.