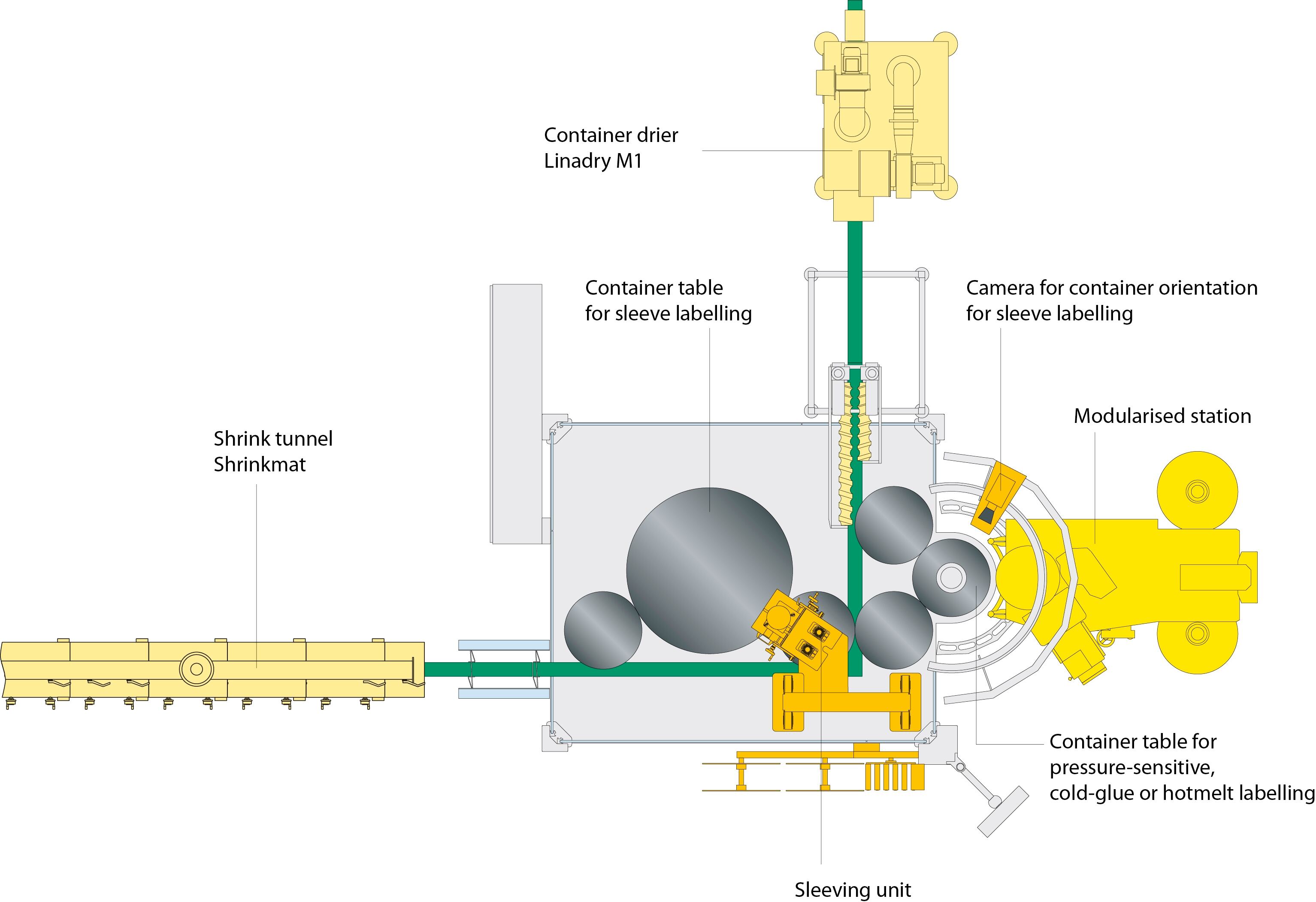

The new DecoBloc features a Sleevematic carousel, a Shrinkmat tunnel and a Linadry unit for predrying containers.

By putting this equipment together, Krones said a system can be created that can cope with all dress variants and therefore offer increased flexibility to beverage manufacturers.

Josef Mayer, product manager at the Krones labelling division, told BeverageDaily.com that the main advantage of the machine is its greater flexibility. He said: “The customer can use all the traditional labeling systems on one machine.”

Krones said that DecoBloc can handle cold-glue, pressure-sensitive, hotmelt or shrink and stretch sleeves – it claims that all these labelling processes can be speedily performed.

Different machine sizes are available, offering output speeds of up to 72,000 containers an hour. And regarding changeover, Krones claims a product change can be made swiftly, at the touch of a button, thanks in part to docking stations that feature motorised height adjustment.

In line with the flexibility theme, for sleeving applications there is a choice between shrink-sleeve labels with a downstream Shrinkmat tunnel or stretch-sleeve labelling.

There is also an option for camera-based alignment of the containers on an embossed marking or a container contour. Krones said this ensures that the labels or sleeves are optimally positioned in relation to the bottle. Servomotors are also used to maximise the accuracy of dress positioning.

Mayer said the system is likely to appeal mainly to soft drink bottlers but may attract interest from convertors.

He said: “The first machine is already installed at a converter for Coca Cola products in Brazil and already labels. A second machine for Naturella Getränke GmbH & Co KG in Germany is about to be delivered.”